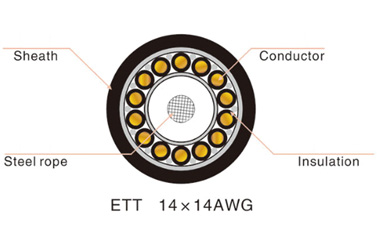

A new hardy special protective rubber that can remain soft at minus 15 degrees. The structure of the cable includes the following components: conductor, insulator, dark color, inner lining, reinforcement, sheath, rated voltage, test voltage, static bending test, vertical combustion test, product standards, and guidelines for use.

Low Speed Elevator Cable conform to the standard to GB/T 5023.6,IEC 60227-6. The operating temperature of low speed elevator cable is between -15℃~+70℃.

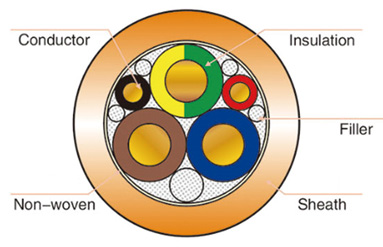

Middle and High Speed Elevator Cable conform to the standard to GB/T 5023.6, IEC 60227-6, and it's strongly against bends.

High Speed Elevator Cable conform to the Standard of GB/T 5023.6 and IEC 60227-6. It has certificate of RoHS and CE.

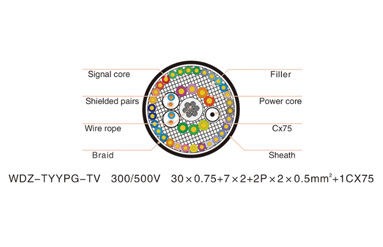

This cable is used for charging tools for electric powered automobile and charging port, and for control systems of charging saturation, safety warning and other control signal transfer function of the vehicle charging and discharging.

The standards for elevator cables are those that include conductors, insulators, dark colors, lining, stiffeners, sheaths, rated voltages, test voltages, static bending tests, vertical combustion tests, product standards, and guidelines for use.

1. The standard of the conductor is that the elevator cable is to be made of multi-strand super-slender and finely calibrated oxygen-free steel wire, and not only that, the standard of the conductor must conform to the VDE0295 CLASS 5 standards;

2. Insulator standard in the above we also mentioned that the use of a special mix of PVC insulation materials;

3. The color of the elevator cable must conform to the GB5023 Standard 6 promulgated by the China government, including yellow, white or orange, etc.

4. Elevator cable without lining;

5. The rated voltage of the elevator cable is 300/50V, while its test voltage is relatively high at 2500V;

6. According to the static bending test of the elevator cable, its bending degree is between 9. 3M and 0.6M;

7. According to the vertical burning test of elevator cable, it is able to pass the test of GB/T18380, 1-2001, IEC60332-1.

Ontil has acquires TUV, UL, CCC, CE, IEC certification.